The use of a soldering oven, solder wave, selective machine or a vapor phase soldering machine requires setting the temperature profile for individual products. It is also advisable to regularly check the settings and calibration of the machines. For this purpose, profilers are used. We offer the most technically advanced profilers available on the market.

The use of a soldering oven, solder wave, selective machine or a vapor phase soldering machine requires setting the temperature profile for individual products. It is also advisable to regularly check the settings and calibration of the machines. For this purpose, profilers are used. We offer the most technically advanced profilers available on the market.

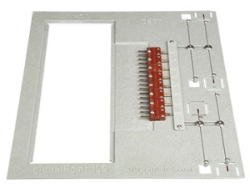

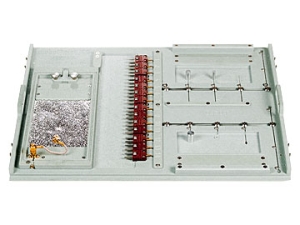

To check the soldering machine calibration, the profilers are equipped with special calibration plates. The plates simulate the soldering of components with different heat capacity located in different positions on the upper and lower sides of the plates.

To check the soldering machine calibration, the profilers are equipped with special calibration plates. The plates simulate the soldering of components with different heat capacity located in different positions on the upper and lower sides of the plates.

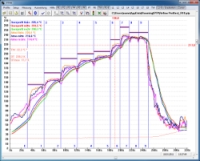

Profiles communicate with a data receiver connected to a PC. The transmission is wireless and takes place in real time, i.e. during the measurement. The software enables further data processing, archiving and statistical functions.

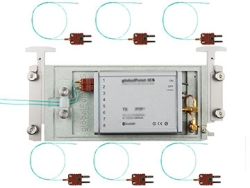

A module with an adjustable base width is available for optimizing the profile in the soldering machine. This allows the temperature sensors to be attached to the printed circuit board and the profiler placed on the machine conveyor directly behind it.

A module with an adjustable base width is available for optimizing the profile in the soldering machine. This allows the temperature sensors to be attached to the printed circuit board and the profiler placed on the machine conveyor directly behind it.

The satisfaction of our customers is the most important thing for us, therefore we make every effort to ensure that orders are carried out quickly and that the offered goods are of the highest quality. Thanks to the commitment of our specialists who are willing to provide advice, shopping in our online store becomes pure pleasure.

LABEM S.C. Stanisław Żochowski, Marek Żochowski

ul. Sibeliusa 22

02-641 Warsaw

office@labem.pl

+48 22 646 27 9

+48 22 844 01 57

Copyright © LABEM S. C.

All rights reserved. Privacy Policy

Made with ♥︎ by Skydoo