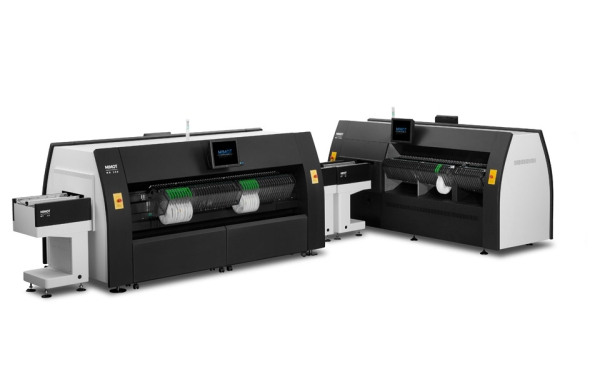

Mimot offers the delivery of complete technological solutions for electronic production. Assembly lines based on Mimot machines are characterized by high flexibility and efficiency. Production capacity is scalable and can be increased as needed. The rich software enables the line integration into the existing structures of your company and facilitates production management, planning and quality control. Please contact us, we provide references.

Mimot offers the delivery of complete technological solutions for electronic production. Assembly lines based on Mimot machines are characterized by high flexibility and efficiency. Production capacity is scalable and can be increased as needed. The rich software enables the line integration into the existing structures of your company and facilitates production management, planning and quality control. Please contact us, we provide references.

What distinguishes Mimot machines from others:

The satisfaction of our customers is the most important thing for us, therefore we make every effort to ensure that orders are carried out quickly and that the offered goods are of the highest quality. Thanks to the commitment of our specialists who are willing to provide advice, shopping in our online store becomes pure pleasure.

LABEM S.C. Stanisław Żochowski, Marek Żochowski

ul. Sibeliusa 22

02-641 Warsaw

office@labem.pl

+48 22 646 27 9

+48 22 844 01 57

Copyright © LABEM S. C.

All rights reserved. Privacy Policy

Made with ♥︎ by Skydoo