The equipment of automatic machines presented below does not close the list of available accessories. Mimot’s policy is flexibility and adaptation of machines to the client’s needs. For many years of activity, the Mimot company has developed many atypical feeders and atypical equipment. If you have specific requirements, please contact us. We will try to solve your problems and select the appropriate machine equipment.

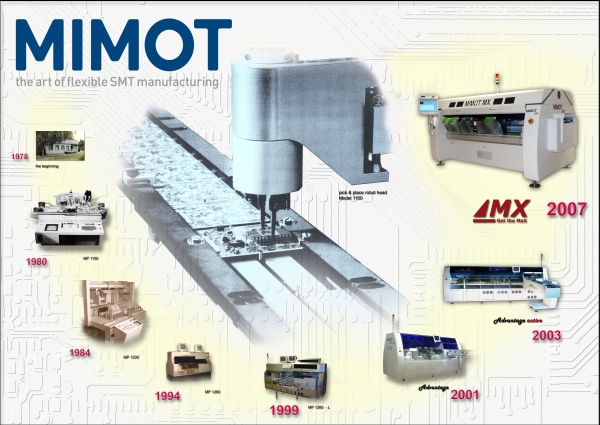

What distinguishes Mimot machines from others:

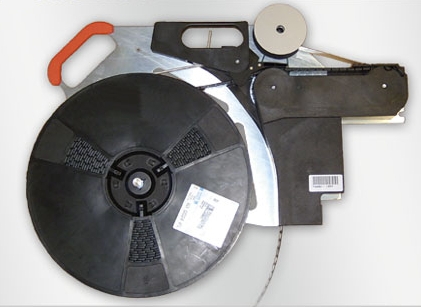

The intelligent feeders of the Triligent system are the heart of the Mimota system. Coded feeders enable their immediate installation, without the need to stop production. The feeder communicates with the software of the machine via a connector enabling quick data exchange. The feeder status is indicated by LEDs. The feeders have been optimized for repeatability of the picking position. The machine management software tells the operator which feeders should be armed and installed before they are even needed. The system predicts which modules will be produced and communicates with the operator well in advance. Arming the feeder is simplified to the limit. During arming, the operator uses a barcode scanner. The management system remembers which feeders are armed, even if they are not installed in the machine. Based on this, the production optimizer always knows which feeders are available and when to change the component on the feeder.

A simple pallet feeder is simply a table placed near the working area on which the pallets with components are placed. The dimensions of the table are 230 mm x 370 mm. Up to 10 types of pallets can be placed on the table.

A simple pallet feeder is simply a table placed near the working area on which the pallets with components are placed. The dimensions of the table are 230 mm x 370 mm. Up to 10 types of pallets can be placed on the table.

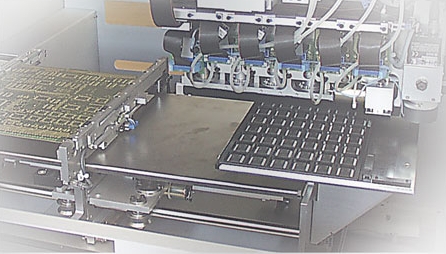

If there are many components on the board taken from pallets, it is worth using the so-called loader. This device does not take up any places in the feeder bank, it is attached to the machine frame. Pallets of the required types are placed on the conveyor of the device and fixed with magnets. Changing the pallets does not require stopping production. The transporter has dimensions of 230mm x 880mm and allows you to put on several pallets.

The pallet changer enables the feeding of components from multiple pallets and their automatic replacement. This is the most flexible solution. In the case of the changer, too, changing the pallet does not require stopping production.

Ergonomic station for arming the feeders.

Special features:

Ergonomic station for arming the feeders.

Special features:

The feeder carts are available in various sizes. They enable comfortable storage of feeders and their transport to the machine. They are suitable for storing all types of feeders. ESD protection.

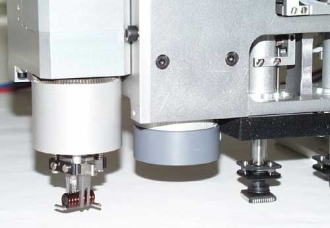

The dispenser can be integrated in the machine head. It is a precision screw dispenser.

Special features:

The dispenser can be integrated in the machine head. It is a precision screw dispenser.

Special features:

The mechanical gripper for unusual details adapts to the customer’s requirements.

Special features:

The mechanical gripper for unusual details adapts to the customer’s requirements.

Special features:

The satisfaction of our customers is the most important thing for us, therefore we make every effort to ensure that orders are carried out quickly and that the offered goods are of the highest quality. Thanks to the commitment of our specialists who are willing to provide advice, shopping in our online store becomes pure pleasure.

LABEM S.C. Stanisław Żochowski, Marek Żochowski

ul. Sibeliusa 22

02-641 Warsaw

office@labem.pl

+48 22 646 27 9

+48 22 844 01 57

Copyright © LABEM S. C.

All rights reserved. Privacy Policy

Made with ♥︎ by Skydoo