Labem | Mimot - MB and MLS machines

Mimot machines

Mimot – MB and MLS machines

Mimot – MB and MLS machines

Mimot – MB and MLS machines

Mimot – MB and MLS machines

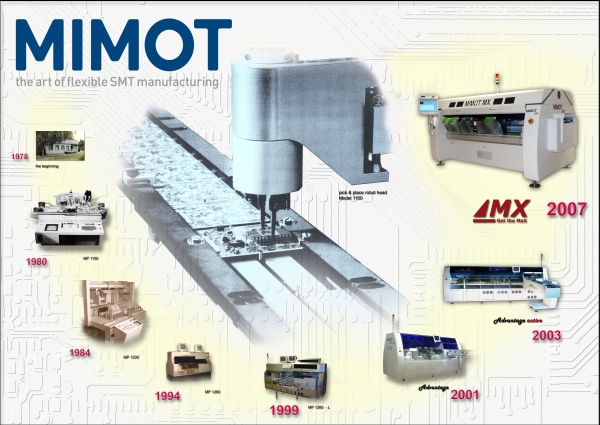

We are pleased to announce that we have started cooperation with a renowned manufacturer of smd assembly machines. The German company MIMOT produces machines for medium and high-performance production. Machines developed since 1978, so from the dawn of surface technology, have become the most flexible and innovative machines available on the market. The technology “Made in Germany” ensures the highest quality and being user-friendly. Mimot offers not only automatic machines. We provide comprehensive customer service, which consists of a training package, implementation of warehouse management software, online remote assistance for users and quick service assistance. We are proud to be able to provide you the highest quality machines.

We are pleased to announce that we have started cooperation with a renowned manufacturer of smd assembly machines. The German company MIMOT produces machines for medium and high-performance production. Machines developed since 1978, so from the dawn of surface technology, have become the most flexible and innovative machines available on the market. The technology “Made in Germany” ensures the highest quality and being user-friendly. Mimot offers not only automatic machines. We provide comprehensive customer service, which consists of a training package, implementation of warehouse management software, online remote assistance for users and quick service assistance. We are proud to be able to provide you the highest quality machines.

What distinguishes Mimot machines from others:

The MB 200 series replaces the Advantage series. This is the basic, modernised series of Mimota machines. Machines are available to install 114, 184, 254 or 324 8mm feeders. Productivity is scalable from 6,000 to 21,600 components per hour, depending on the number of heads installed. The assembly of additional heads is quick and does not require the transport of the machine to the manufacturer.

Special features:

The MB 200 series replaces the Advantage series. This is the basic, modernised series of Mimota machines. Machines are available to install 114, 184, 254 or 324 8mm feeders. Productivity is scalable from 6,000 to 21,600 components per hour, depending on the number of heads installed. The assembly of additional heads is quick and does not require the transport of the machine to the manufacturer.

Special features:

The Mimot MB 300 series of machines is designed for high-performance production. It is characterized by efficiency up to max. 32,000 components per hour.

Special features:

The Mimot MB 300 series of machines is designed for high-performance production. It is characterized by efficiency up to max. 32,000 components per hour.

Special features:

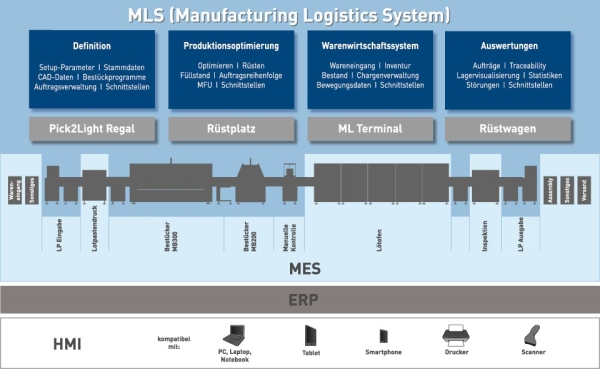

The task of the Manufacturing Logistics Systems (MLS) system is to minimize the time needed to equip the machines and provide all materials, feeders and components necessary for the operation of the SMD line. With the help of the MLS system, the downtime of the production line can be significantly reduced or eliminated. The MLS system consists of a Manufacturing Logistics Terminal (MLT), an integrated set-up and programming station for feeders, Pick2Light racks, feeder cart and software.

The individual MLS parts work together in a comprehensive MIMOT-Setup-Circle system to ensure the highest possible production efficiency and effectiveness. All data on feeders, stored components, component deliveries, production times of individual products, line performance are integrated in the software system. The line operator receives all the necessary information. The MLS system significantly simplifies the activities related to production. The operator’s reaction time is shortened, the number of errors is reduced and, consequently, the efficiency of the SMT line increases.

MIMOT-Setup-Circle takes into account all the constituent parts of the line, not just the components – it is much more than “Pick & Place”!

The Manufacturing Logistics terminal, which is part of the MLS system, is used to set up and store feeders and to store and share components and materials necessary in the production process.

Special features:

The task of the Manufacturing Logistics Systems (MLS) system is to minimize the time needed to equip the machines and provide all materials, feeders and components necessary for the operation of the SMD line. With the help of the MLS system, the downtime of the production line can be significantly reduced or eliminated. The MLS system consists of a Manufacturing Logistics Terminal (MLT), an integrated set-up and programming station for feeders, Pick2Light racks, feeder cart and software.

The individual MLS parts work together in a comprehensive MIMOT-Setup-Circle system to ensure the highest possible production efficiency and effectiveness. All data on feeders, stored components, component deliveries, production times of individual products, line performance are integrated in the software system. The line operator receives all the necessary information. The MLS system significantly simplifies the activities related to production. The operator’s reaction time is shortened, the number of errors is reduced and, consequently, the efficiency of the SMT line increases.

MIMOT-Setup-Circle takes into account all the constituent parts of the line, not just the components – it is much more than “Pick & Place”!

The Manufacturing Logistics terminal, which is part of the MLS system, is used to set up and store feeders and to store and share components and materials necessary in the production process.

Special features:

The satisfaction of our customers is the most important thing for us, therefore we make every effort to ensure that orders are carried out quickly and that the offered goods are of the highest quality. Thanks to the commitment of our specialists who are willing to provide advice, shopping in our online store becomes pure pleasure.

LABEM S.C. Stanisław Żochowski, Marek Żochowski

ul. Sibeliusa 22

02-641 Warsaw

office@labem.pl

+48 22 646 27 9

+48 22 844 01 57

Copyright © LABEM S. C.

All rights reserved. Privacy Policy

Made with ♥︎ by Skydoo