Labem | MIMOT - CONSTRUCTION CONCEPT AND SPECIAL FEATURES

Mimot machines

Construction concept and special features

Construction concept and special features

Construction concept and special features

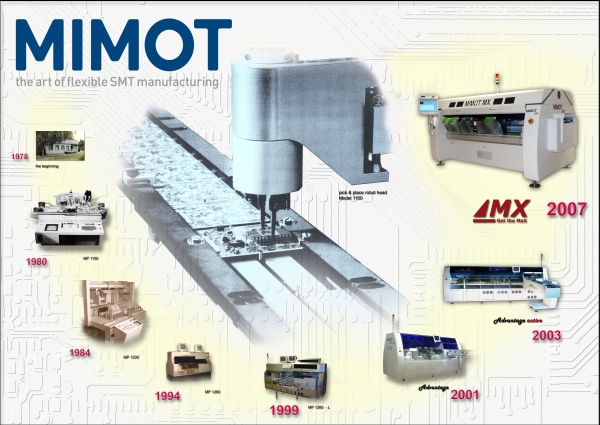

The Mimot company has been producing SMD assembly machines for 30 years. The company was founded in 1978 and two years later the first machine for assembling surface components was built. The company’s headquarters and production plant are located in Germany. Mimot specializes in the production of efficient automatic machines intended for short-series production. Special design features and software make it possible to optimize production tasks and minimize downtime. Please contact us by phone – our engineer will provide full information about the machines.

The Mimot company has been producing SMD assembly machines for 30 years. The company was founded in 1978 and two years later the first machine for assembling surface components was built. The company’s headquarters and production plant are located in Germany. Mimot specializes in the production of efficient automatic machines intended for short-series production. Special design features and software make it possible to optimize production tasks and minimize downtime. Please contact us by phone – our engineer will provide full information about the machines.

The development of the concept of building Mimot machines is influenced by 30 years of experience. During this time, Mimot paid close attention to the requirements of individual clients. As a result, very flexible machines were created that can be adapted to very unusual requirements. The machines adapt very flexibly to the production profile, their construction allows for easy extension of their capabilities as the needs grow. This applies to both increasing efficiency as well as the use of additional software modules and technical solutions. It is possible, for example, to develop or use non-standard feeders, dosing modules, and non-standard tools. Mimot always responds to the client’s requests. You can count on help in solving production problems. Machines can be easily integrated with existing logistics, procurement, planning and quality control systems.

MB series machines are available in several basic versions, enabling the installation of 114, 184, 254 or 324 8mm feeders. Productivity is scalable from 6,000 to 21,600 components per hour. Installing additional performance heads is quick and easy. It is not necessary to transport the machine to the manufacturer. Similarly, the installation of additional centering cameras, dispenser, non typical feeder, modification of the tool kit is not a complicated procedure. As standard, the machines are adapted to work in line, but you can install a manual board feeder and replace it quickly with an inline feeder if necessary.

MB series machines are available in several basic versions, enabling the installation of 114, 184, 254 or 324 8mm feeders. Productivity is scalable from 6,000 to 21,600 components per hour. Installing additional performance heads is quick and easy. It is not necessary to transport the machine to the manufacturer. Similarly, the installation of additional centering cameras, dispenser, non typical feeder, modification of the tool kit is not a complicated procedure. As standard, the machines are adapted to work in line, but you can install a manual board feeder and replace it quickly with an inline feeder if necessary.

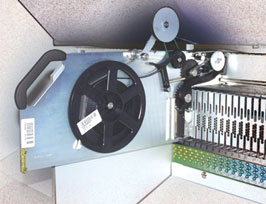

Intelligent feeders must enable the operator to quickly change the machine and ensure easy operation. Coded feeders for immediate installation are the heart of the Mimota system. The machine management software will tell the operator which feeders should be armed and installed before they are even needed. The system predicts which modules will be produced and communicates with the operator well in advance. Arming the feeder is simplified to the limit. During arming, the operator uses a barcode scanner. The management system remembers which feeders are armed, even if they are not installed in the machine. Based on this, the production optimizer always knows what feeders are available and when to change the component on the feeder. The system also enables integration in the corporate network and connection with the warehouse and procurement department. 100% reverse tracking is ensured

The Truth About efficiency:

Mimot’s customers can easily get answers to these questions. The machine software allows you to obtain rich data and production statistics. Unfortunately, knowing the theoretical efficiency of the machine is not enough. The standards only define the maximum that can be achieved under the optimistic conditions. Only a thorough analysis of the actual production can determine the efficiency. If there is no processing capacity – it is not a problem. Advantage machines allow for quick installation of additional heads and centering cameras. This is the main advantage of modular machine building. The machine will “grow” as needed.

When purchasing a machine, Mimot performs tests on real customer boards and the required performance is determined. You can increase this capacity in the future.

The Truth About efficiency:

Mimot’s customers can easily get answers to these questions. The machine software allows you to obtain rich data and production statistics. Unfortunately, knowing the theoretical efficiency of the machine is not enough. The standards only define the maximum that can be achieved under the optimistic conditions. Only a thorough analysis of the actual production can determine the efficiency. If there is no processing capacity – it is not a problem. Advantage machines allow for quick installation of additional heads and centering cameras. This is the main advantage of modular machine building. The machine will “grow” as needed.

When purchasing a machine, Mimot performs tests on real customer boards and the required performance is determined. You can increase this capacity in the future.

The software modules developed by Mimot are not only used to control machines. It is possible to develop and integrate the IT system of the production line with the existing IT system of the client, e.g. with SAP. There are modules for managing the warehouse of components, support systems and production planning.

The Manufacturing Logistics system with the MLT terminal allows you to concentrate the management of the warehouse of components and the production line in one place.

Appropriate selection of software will enable and facilitate appropriate warehouse management, support the planning department and ensure performance control to managing directors.

Quality control and service can also use the Mimota software. 100% traceability is ensured. If the boards have a barcode, the software will check which components, from which suppliers and when were used on them.

The software modules developed by Mimot are not only used to control machines. It is possible to develop and integrate the IT system of the production line with the existing IT system of the client, e.g. with SAP. There are modules for managing the warehouse of components, support systems and production planning.

The Manufacturing Logistics system with the MLT terminal allows you to concentrate the management of the warehouse of components and the production line in one place.

Appropriate selection of software will enable and facilitate appropriate warehouse management, support the planning department and ensure performance control to managing directors.

Quality control and service can also use the Mimota software. 100% traceability is ensured. If the boards have a barcode, the software will check which components, from which suppliers and when were used on them.

The satisfaction of our customers is the most important thing for us, therefore we make every effort to ensure that orders are carried out quickly and that the offered goods are of the highest quality. Thanks to the commitment of our specialists who are willing to provide advice, shopping in our online store becomes pure pleasure.

LABEM S.C. Stanisław Żochowski, Marek Żochowski

ul. Sibeliusa 22

02-641 Warsaw

office@labem.pl

+48 22 646 27 9

+48 22 844 01 57

Copyright © LABEM S. C.

All rights reserved. Privacy Policy

Made with ♥︎ by Skydoo