The SEHO company is one of the largest manufacturers of soldering machines in the world. It offers the highest quality soldering machines.

SEHO machines work in many companies in Poland. We provide references.

Small wave solder with spray fluxer for production in lead-free technology.

A new type of EnergyWave turbulent nozzle.

Small wave solder with spray fluxer for production in lead-free technology.

A new type of EnergyWave turbulent nozzle.

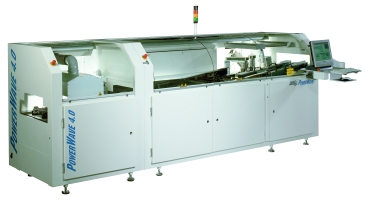

Solder wave with spray fluxer for production in lead-free technology. Solder wave for high-efficient production with chain transport, single or double.

A new type of EnergyWave turbulent nozzle.

Possibility of extending heating zones, installing a nitrogen head, automatic control of the solder level.

Solder wave with spray fluxer for production in lead-free technology. Solder wave for high-efficient production with chain transport, single or double.

A new type of EnergyWave turbulent nozzle.

Possibility of extending heating zones, installing a nitrogen head, automatic control of the solder level.

The smallest solder wave with a nitrogen tunnel

The smallest solder wave with a nitrogen tunnel

Waves with nitrogen tunnels designed for high-efficient production.

Waves with nitrogen tunnels designed for high-efficient production.

For soldering waves, SEHO offers transport lines: loading and unloading stations, buffers, elevators and other elements of the production line. At your request, we will configure the appropriate system, send technical data and a price offer.

The satisfaction of our customers is the most important thing for us, therefore we make every effort to ensure that orders are carried out quickly and that the offered goods are of the highest quality. Thanks to the commitment of our specialists who are willing to provide advice, shopping in our online store becomes pure pleasure.

LABEM S.C. Stanisław Żochowski, Marek Żochowski

ul. Sibeliusa 22

02-641 Warsaw

office@labem.pl

+48 22 646 27 9

+48 22 844 01 57

Copyright © LABEM S. C.

All rights reserved. Privacy Policy

Made with ♥︎ by Skydoo