Labem | Positioning and soldering stations

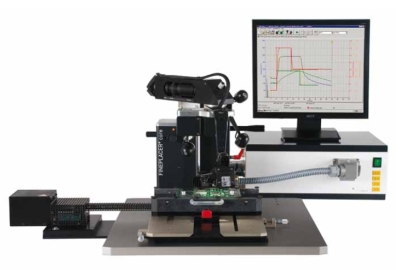

Rework stations - positioning and soldering

In our offer you will find various service stations for QFP, BGA, uBGA, etc. The models listed below differ significantly in technical parameters and the possibility of their application to various types of systems. Please contact us by phone. We will send you detailed data and prices.

In our offer you will find various service stations for QFP, BGA, uBGA, etc. The models listed below differ significantly in technical parameters and the possibility of their application to various types of systems. Please contact us by phone. We will send you detailed data and prices.