BT 301 Autotronik is a convection chamber oven. Perfect for the production of small series or prototypes. Its advantages are small dimensions and microprocessor control ensuring high quality of soldering

BS 551 is an efficient soldering reflow oven with forced convection. Four upper + four lower heating zones, microprocessor control with a

7 ″touch panel. It enables soldering of circuit boards up to 405 mm wide. Three-phase power supply, power 12kW. Built-in two exhaust zones and cooling zone. The software enables easy control of the soldering process.

BS 551 is an efficient soldering reflow oven with forced convection. Four upper + four lower heating zones, microprocessor control with a

7 ″touch panel. It enables soldering of circuit boards up to 405 mm wide. Three-phase power supply, power 12kW. Built-in two exhaust zones and cooling zone. The software enables easy control of the soldering process.

The SEHO company is one of the largest manufacturers of soldering machines in the world. It offers the highest quality soldering machines.

SEHO machines work in many companies in Poland. We provide references.

The SEHO company is one of the largest manufacturers of soldering machines in the world. It offers the highest quality soldering machines.

SEHO machines work in many companies in Poland. We provide references.

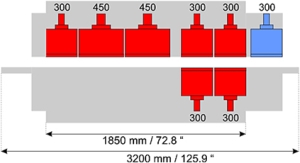

Seho engineers keep improving the basic model of the reflow oven. GoReflow allows the installation of a nitrogen tunnel. The machine has very efficient heating zones, the peak zone is double. GoReflow is an efficient industrial reflow oven with full forced convection. Two models are available with chamber lengths of 1800 and 2300 mm. Mesh, chain or mixed transport. They are equipped with cooling fans. Control by touch panel or by computer (optional). Lower heating zones (optional).

eho engineers keep improving the basic model of the reflow oven. GoReflow allows the installation of a nitrogen tunnel. The machine has very efficient heating zones, the peak zone is double. GoReflow is an efficient industrial reflow oven with full forced convection. Two models are available with chamber lengths of 1800 and 2300 mm. Mesh, chain or mixed transport. They are equipped with cooling fans. Control by touch panel or by computer (optional). Lower heating zones (optional).

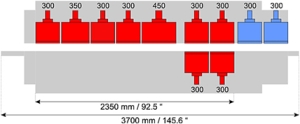

The new GoReflow Plus is a model slightly smaller than the MaxiReflow. It is based on the same innovative technology as GoReflow, but it is slightly larger and has more optional equipment. The length of the heating zones is 3000 mm. It has 8 top and 8 bottom heating zones – 3 last zones are peak zones. GoReflow Plus ranks between GoReflow and MaxiReflow in terms of performance, equipment and price.

The new GoReflow Plus is a model slightly smaller than the MaxiReflow. It is based on the same innovative technology as GoReflow, but it is slightly larger and has more optional equipment. The length of the heating zones is 3000 mm. It has 8 top and 8 bottom heating zones – 3 last zones are peak zones. GoReflow Plus ranks between GoReflow and MaxiReflow in terms of performance, equipment and price.

The satisfaction of our customers is the most important thing for us, therefore we make every effort to ensure that orders are carried out quickly and that the offered goods are of the highest quality. Thanks to the commitment of our specialists who are willing to provide advice, shopping in our online store becomes pure pleasure.

LABEM S.C. Stanisław Żochowski, Marek Żochowski

ul. Sibeliusa 22

02-641 Warsaw

office@labem.pl

+48 22 646 27 9

+48 22 844 01 57

Copyright © LABEM S. C.

All rights reserved. Privacy Policy

Made with ♥︎ by Skydoo